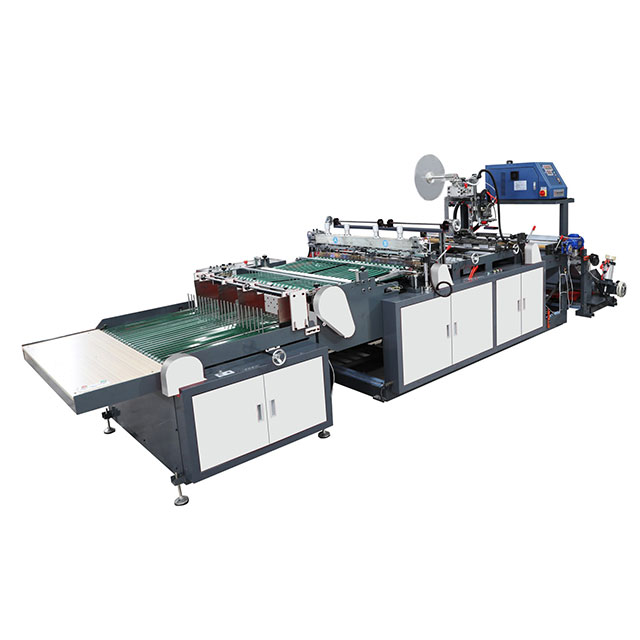

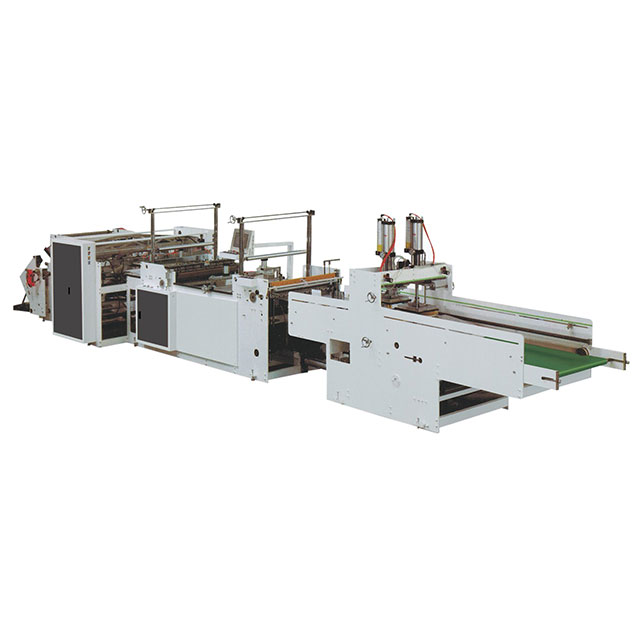

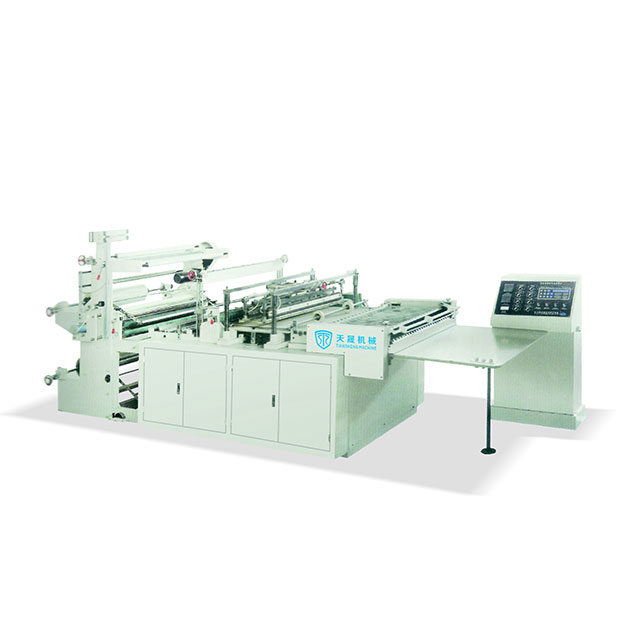

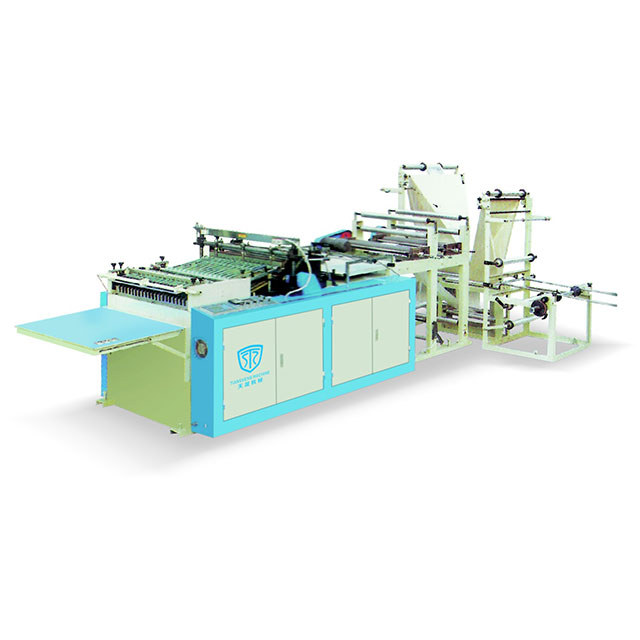

TS-KD-1200 Courier Bag Making Machine

TS-KD-1200

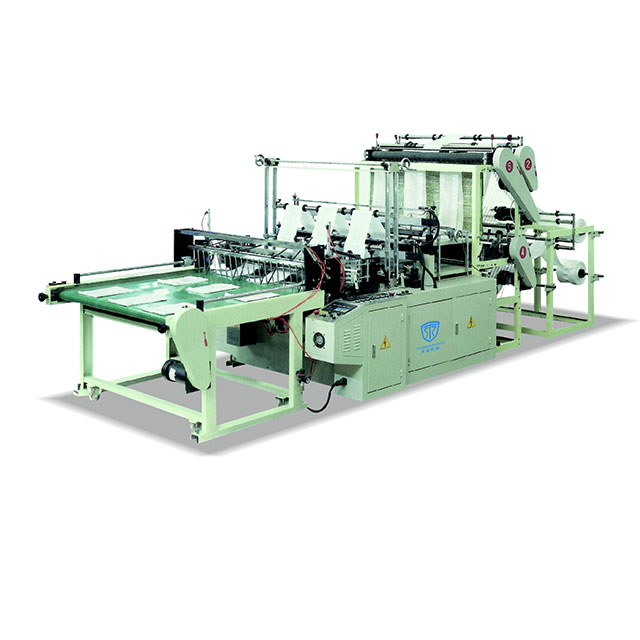

1. Arbitrary fixed length, high-precision photoelectric tracking, accurate, stable, automatic shutdown alarm if the mark is lost.

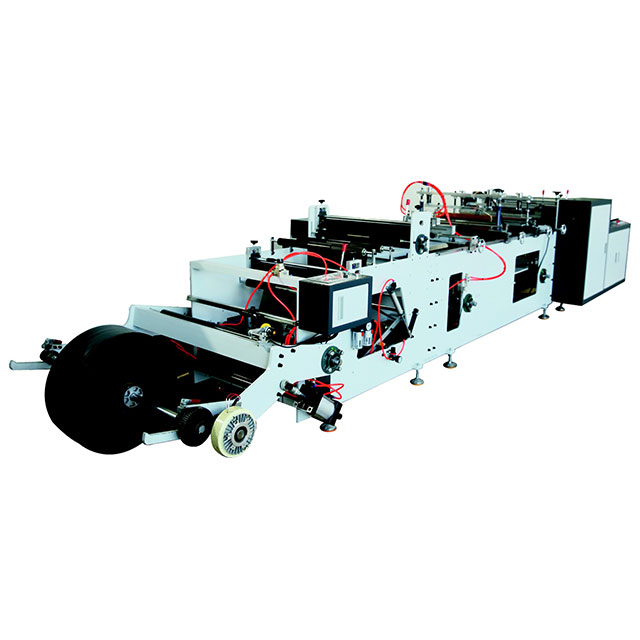

2. Automatic feeding, automatic deviation correction, stable operation.

3. The hot cutting knife is specially treated, the bag cutting is smooth without sticking to the knife, the hot line is firm, and the welding edge is smooth.

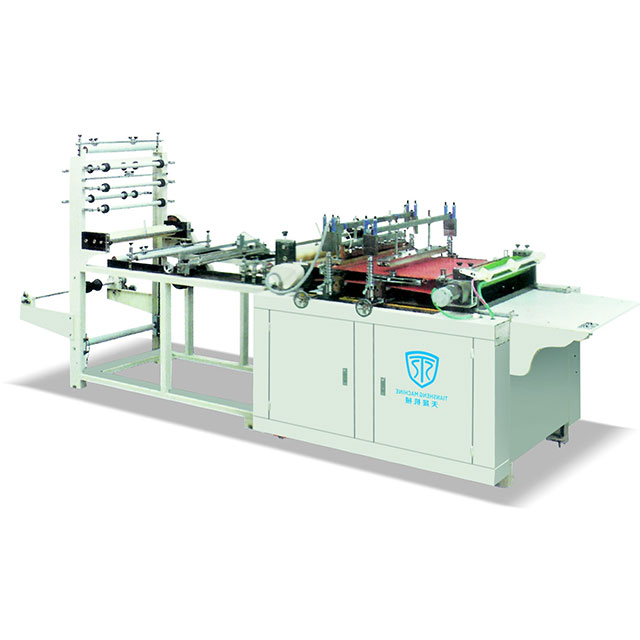

4. The rectifying and unloading rack is made of laser-cut forming steel plate as the main frame, and the guide roller is hard anodizedCatheter, 2 sets of domestic electric eye tracking, photoelectric deviation correction system, magnetic powder automatic tension control,Pneumatic feeding, inflatable shaft discharging.

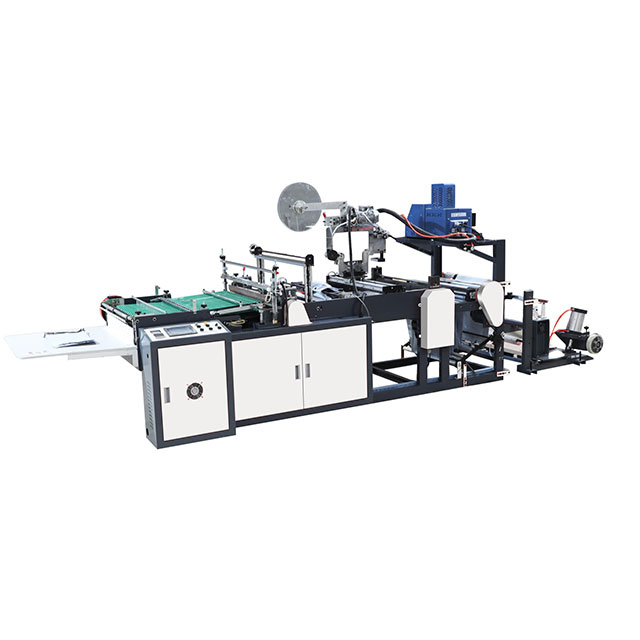

5. Equipped with 1 hot melt glue machine, with double gun heads, can set the automatic glue breaking function, isolationMembrane gluing device, frequency conversion control can adjust the amount of glue.

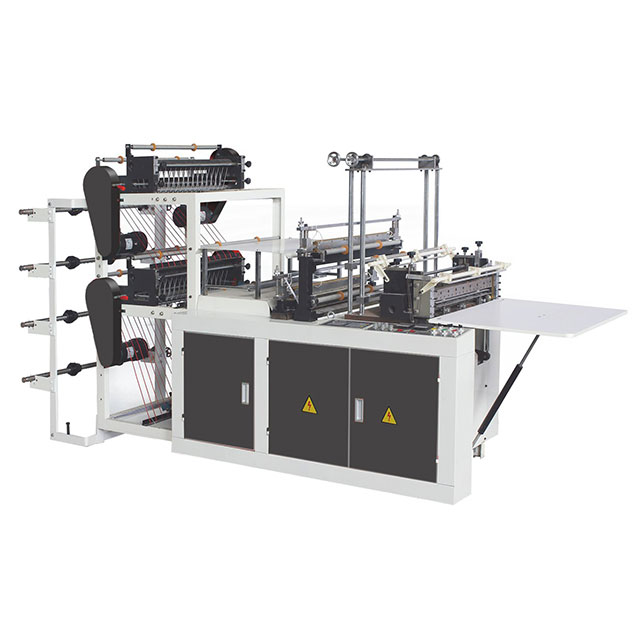

2. Automatic feeding, automatic deviation correction, stable operation.

3. The hot cutting knife is specially treated, the bag cutting is smooth without sticking to the knife, the hot line is firm, and the welding edge is smooth.

4. The rectifying and unloading rack is made of laser-cut forming steel plate as the main frame, and the guide roller is hard anodizedCatheter, 2 sets of domestic electric eye tracking, photoelectric deviation correction system, magnetic powder automatic tension control,Pneumatic feeding, inflatable shaft discharging.

5. Equipped with 1 hot melt glue machine, with double gun heads, can set the automatic glue breaking function, isolationMembrane gluing device, frequency conversion control can adjust the amount of glue.

6. Counting stacking and automatic receiving rack can be set.

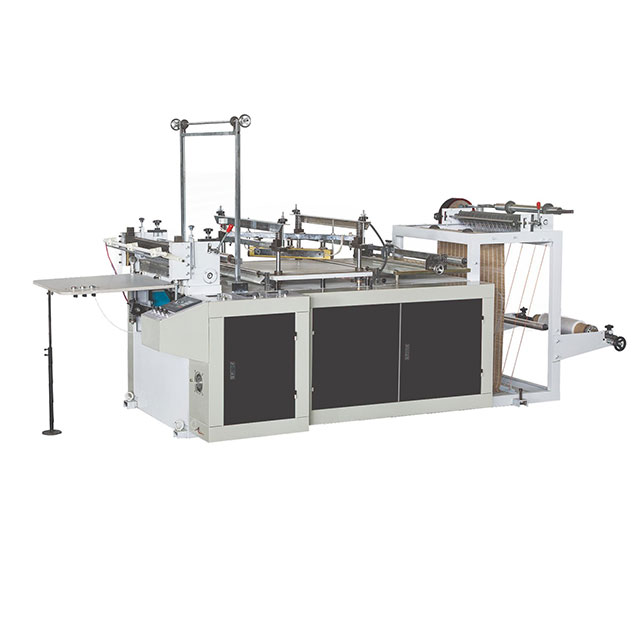

| Model | TS-KD-1200 |

| Unwinding Diameter | Ф 550mm |

| Bag Making Material | PE film, environmental protection film, recycled material |

| Bag Width | ≤450mm |

| Bag Length | 70-650mm |

| Mechanical Top Speed | 50-200 times / min |

| Voltage | 220V/50Hz |

| Total Power | 15kw + glue sprayer 3.3kw |

| Control System | Leisai operation control system is adopted to control, and the operation is more stable |

| Servo Drive System | 4 sets of domestic 3KW servo driver + servo motor, constant tension and fixed length, which can complete the function of automatic glue breaking |

| Main Motor | Domestic three-phase 2.2kW frequency conversion braking motor + frequency converter speed regulation, responsible for knife ironing |