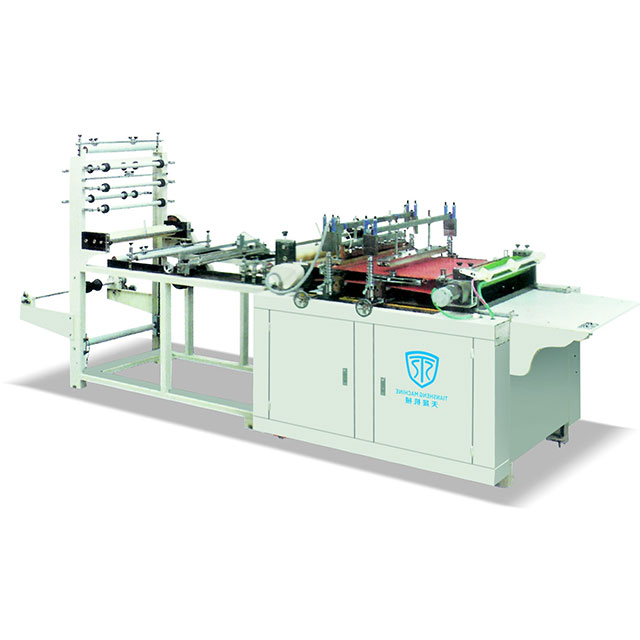

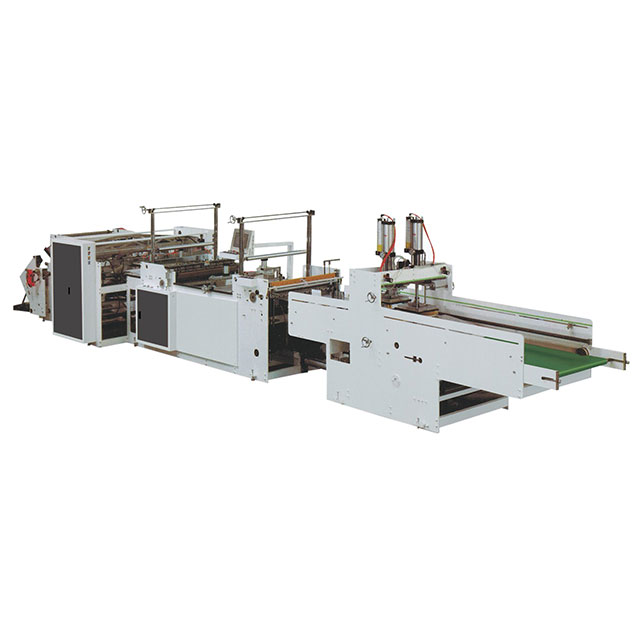

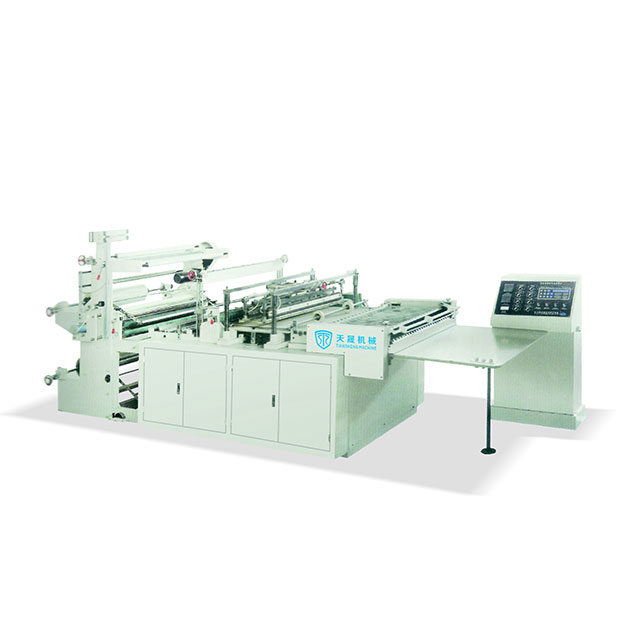

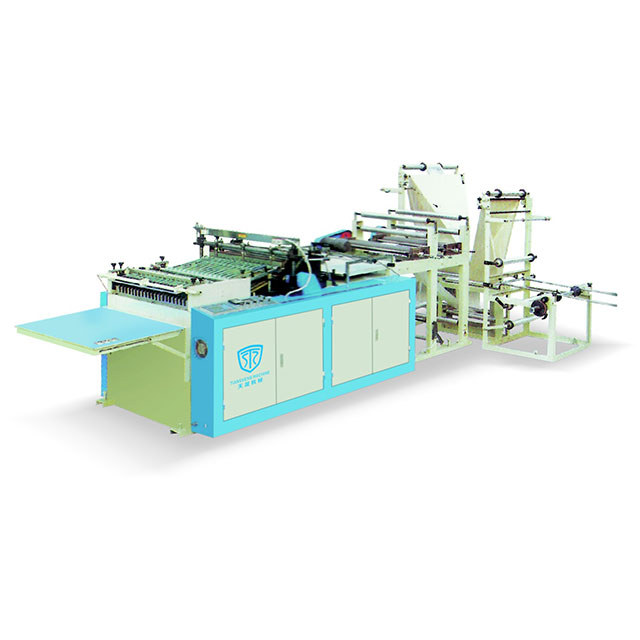

You are here:Home » Products » Bag Making Machine » TS-FHXF1500Composite Bubble Envelope Bag Making Machine

TS-FHXF1500Composite Bubble Envelope Bag Making Machine

TS-FHXF1500

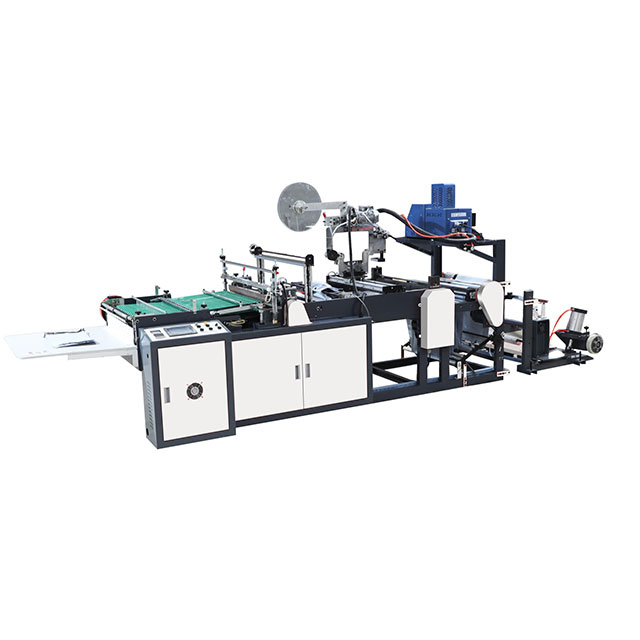

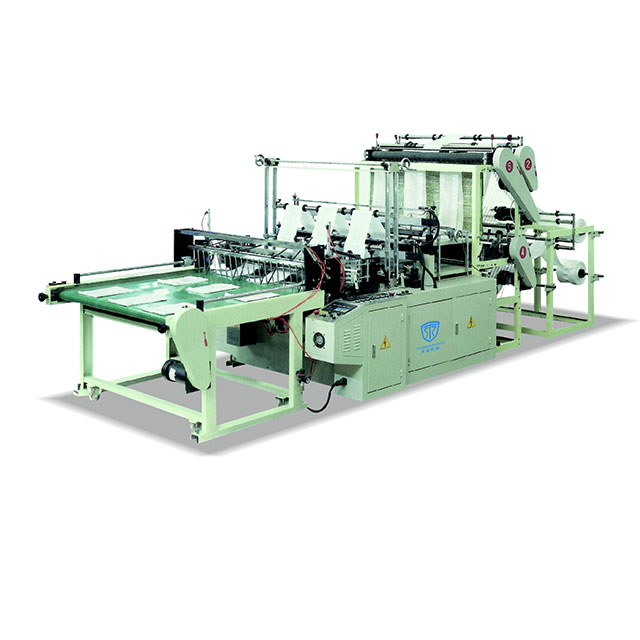

The printing point tracking is controlled by the optical electric eye made in Italy.

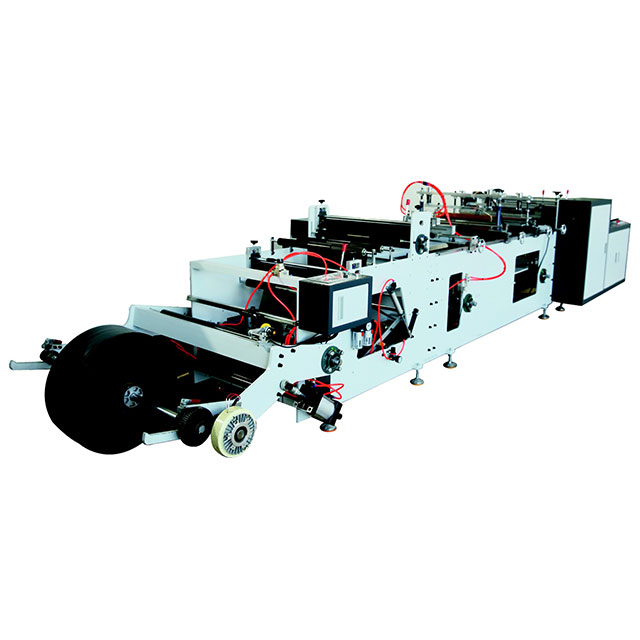

Unwinding is EPC tracking automatic tension double work position unwinding.

Fold one side inward and two out The triangle is folded in half.

The rear feeding traction is controlled by frequency converter and analog quantity superposition function.

The workbench is of automatic bag collection and conveying type. (when the counter reaches the number, the conveyor belt is widened and the number is distinguished)

Of the entire transmission bandwidth.

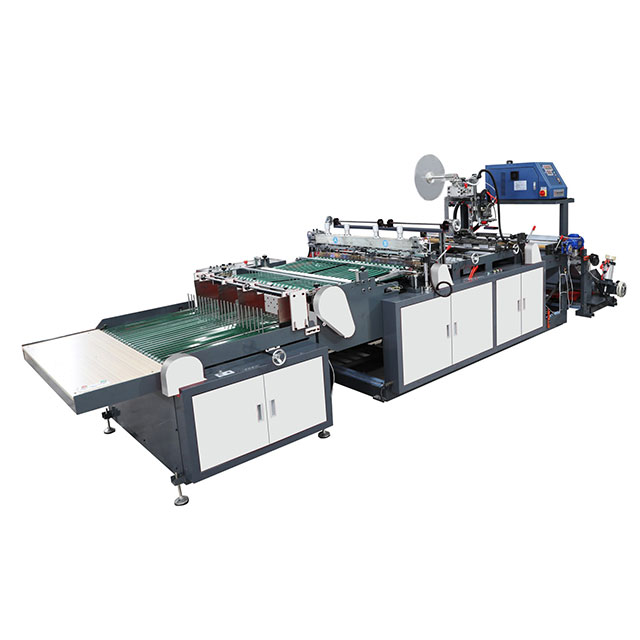

The latest design of the front support synchronous belt is transmitted side by side to ensure that the bubbles are not broken.

A set of cold cutting knife unit adopts steel die-casting cold cutting knife, which can automatically chase the edge so that it has no large and small edges.

Four sets of heat sealing knife units adopt mechanical heating up and down.

One set of bubble crushing unit adopts customized needle pad.

One set of edge sealing cooling unit adopts water cooling mode.

A set of color code tracking unit is mechanically and manually adjustable.

One out, one out.

PE film pressing device

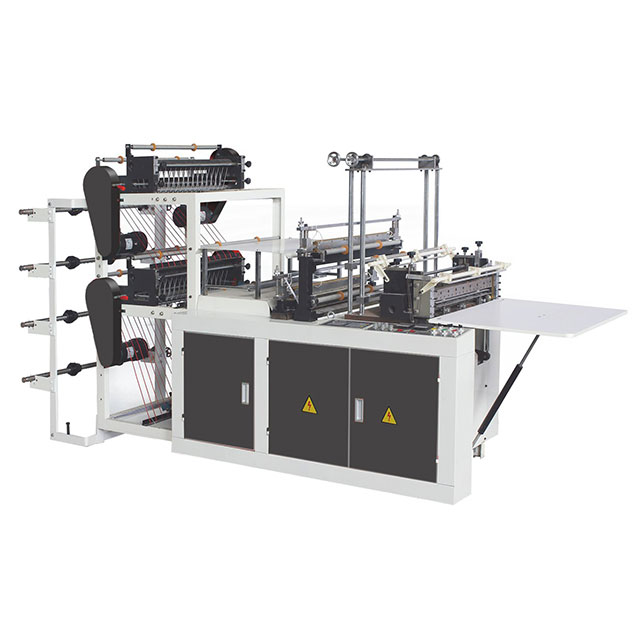

Unwinding is EPC tracking automatic tension double work position unwinding.

Fold one side inward and two out The triangle is folded in half.

The rear feeding traction is controlled by frequency converter and analog quantity superposition function.

The workbench is of automatic bag collection and conveying type. (when the counter reaches the number, the conveyor belt is widened and the number is distinguished)

Of the entire transmission bandwidth.

The latest design of the front support synchronous belt is transmitted side by side to ensure that the bubbles are not broken.

A set of cold cutting knife unit adopts steel die-casting cold cutting knife, which can automatically chase the edge so that it has no large and small edges.

Four sets of heat sealing knife units adopt mechanical heating up and down.

One set of bubble crushing unit adopts customized needle pad.

One set of edge sealing cooling unit adopts water cooling mode.

A set of color code tracking unit is mechanically and manually adjustable.

One out, one out.

PE film pressing device

A set of main control electrical cabinet unit includes display screen, frequency converter, driver, etc.

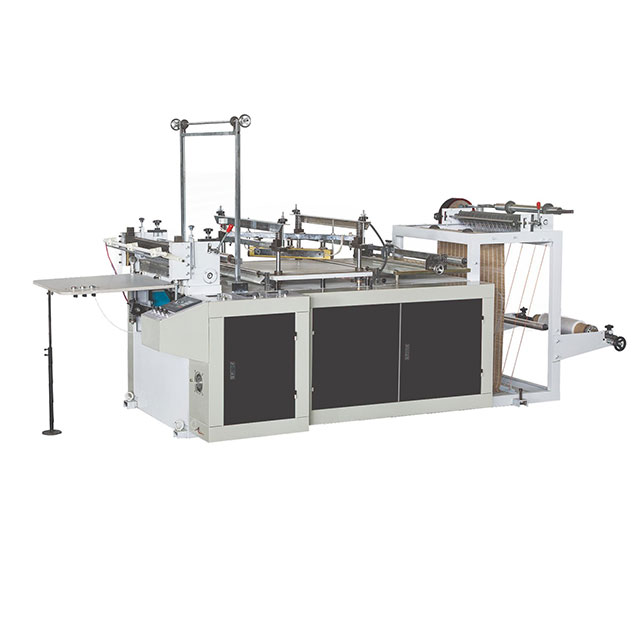

| Model | TS-FHXF1500 |

| Maximum substrate width | 1500mm |

| Maximum discharge diameter | ф1400 |

| Bag making speed | 20-120pcs/min |

| Bag length | 200-650mm |

| Bag making width | 650mm |

| power supply | 380V 三相四线 |

| Machine weight | 4500KG |

| Total power | 30KW |

| Host | 交流电机 |