You are here:Home » Products » Other Related Machine » TS-LΦ 55/90/55x1850Fully high speed 3 layers co-extrusion PE cling film machine group

TS-LΦ 55/90/55x1850Fully high speed 3 layers co-extrusion PE cling film machine group

TS-LΦ 55/90/55x1850

The alloy screw adopts special mixing function and high plasticizing performance design which

combines the imported static mixer to ensure the good plasticization, uniform color and great increase

in the extruding capacity.

The T-die is made of imported high quality mould steel which is processed by high accuracy treatment

it prevents fhe T-die from deformation in long time usage and the casting is smoother and more

stable.

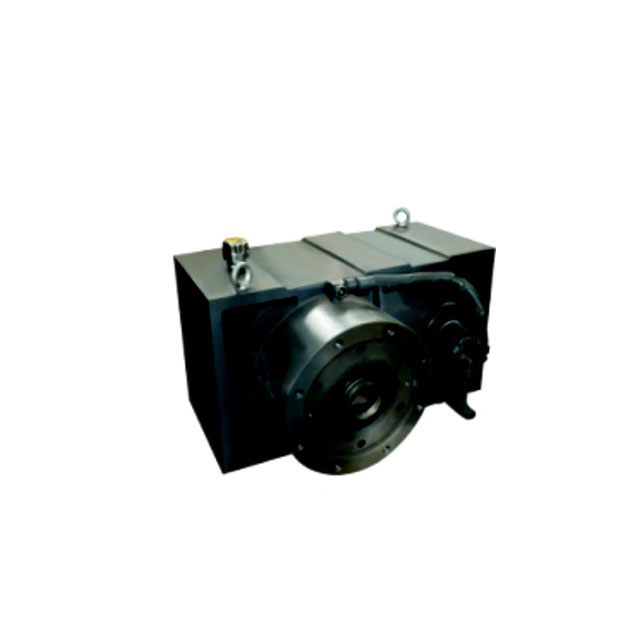

The design inside the cooling roller Is bi-directional and in circuit. The roller is with built-in spiral

runner which ensures the even surface temperature.

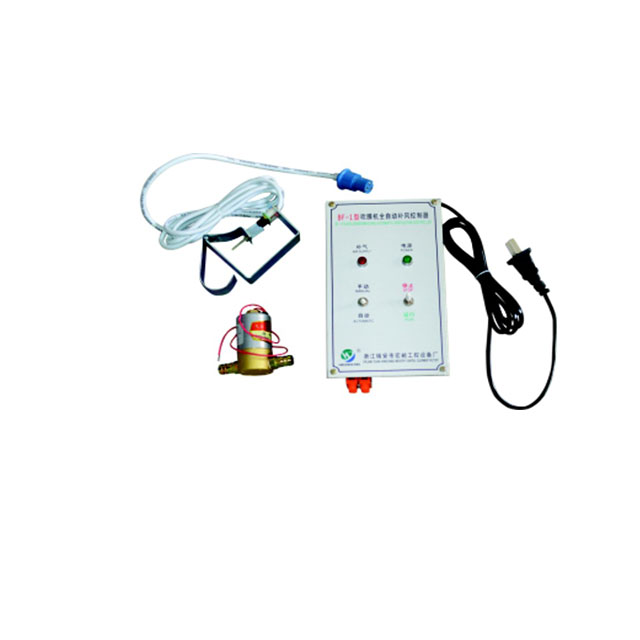

The winding station can move back and forth.It adopts advanced torque motor which can adjust the

speed and the width of the film freely.

combines the imported static mixer to ensure the good plasticization, uniform color and great increase

in the extruding capacity.

The T-die is made of imported high quality mould steel which is processed by high accuracy treatment

it prevents fhe T-die from deformation in long time usage and the casting is smoother and more

stable.

The design inside the cooling roller Is bi-directional and in circuit. The roller is with built-in spiral

runner which ensures the even surface temperature.

The winding station can move back and forth.It adopts advanced torque motor which can adjust the

speed and the width of the film freely.

| Model | TS-LΦ 55/90/55x1850 |

| Screw Diameter | Φ55/90/55mm |

| Screw L / D | 30:1 |

| Screw Speed | 50-150rpm |

| Width | 200-1500mm ( 3x500mm ) |

| Total Power | 130kw |

| Thickness | 0.01-0.05mm |

| Capacity | 50-280kg/h |

| Layer Structure | ABC/ACBCA |

| Total Weight | 11T |

| Dimension (mm) | (L)11000x(W)3600x(H)3800 |