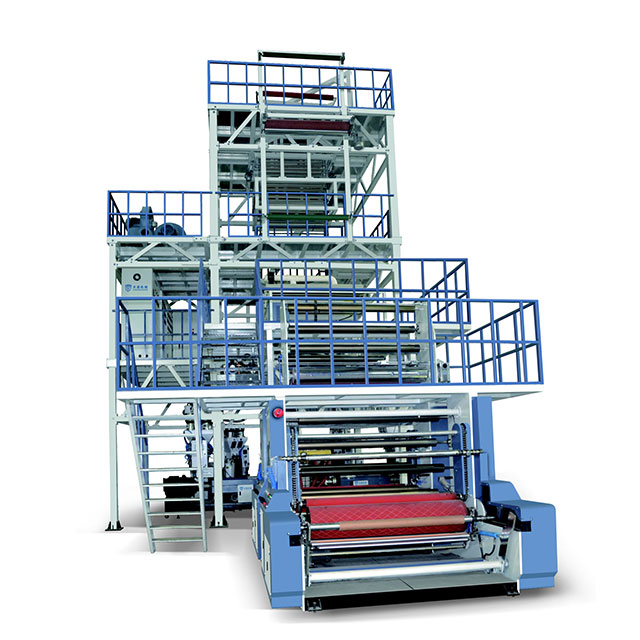

TS-GS1700Layer 3 - Layer 5-extruded Blown Film Crew The Ibc Vesicular Cold Type)

1.The new type of extrusion technology, production (production capacity more than 30%), while And good plasticizing properties.

2.The new technology center feeding spiral die, compact, quick-change Recipes, saving raw materials.

3.IBC cooling device inside the bubble, not only to increase production, reduce energy consumption, but also Improve the quality of film products.

4.Horizontal rotary film traction system, greatly enhance the quality of the film roll, DU Flounced phenomenon must adapt to high-speed printing, complex treatment processes.

5.Automatic duplex winder with automatic roll changing, cutting film, remember m power Energy.

6.Precision dual air suction air ring.

7.Rack surface using advanced paint process, looks nice, Long life, anti-rust performance outstanding.

8.Emphasis on economic blown film equipment devices, high capacity and low power consumption, Good value for money, honesty is the ideal choice for our customers.

| Model | TS-GS1700 |

| Layers | 3 |

| Film Max.Folding | 1600mm |

| Film thickness | 0.03-0.12mm |

| The maximum yield | 250-300kg/h |

| Use of raw materials | MLLDPE,LLDPE,LDPE,EVA |

| Screw diameter | ¢55-¢65-¢55 |

| Screw length | 30:1 |

| Screw Speed | 120r/min |

| Main motor power | 22/37/22kw |

| Bubble cooling form | Precise double-lip air ring,IBC ( internal bubble cooling ) system |

| Traction in the form of rotation | 360 degree horizontal rotation traction system |

| Traction speed | 45-120min |

| Total power | 220kw |

| Dimensions (LxWxH) | 11000x7000x10000mm |

| Weight | 30T |