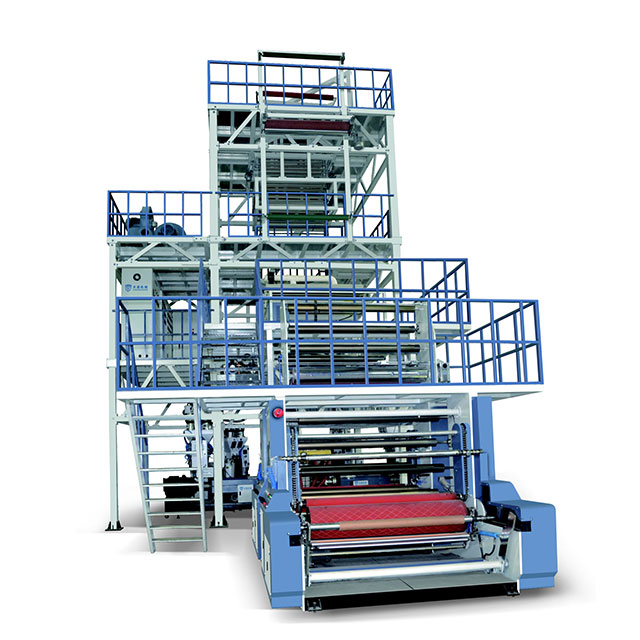

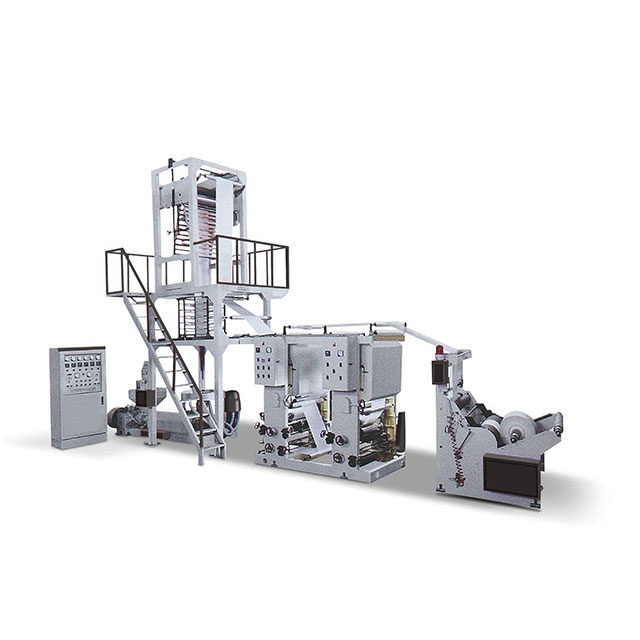

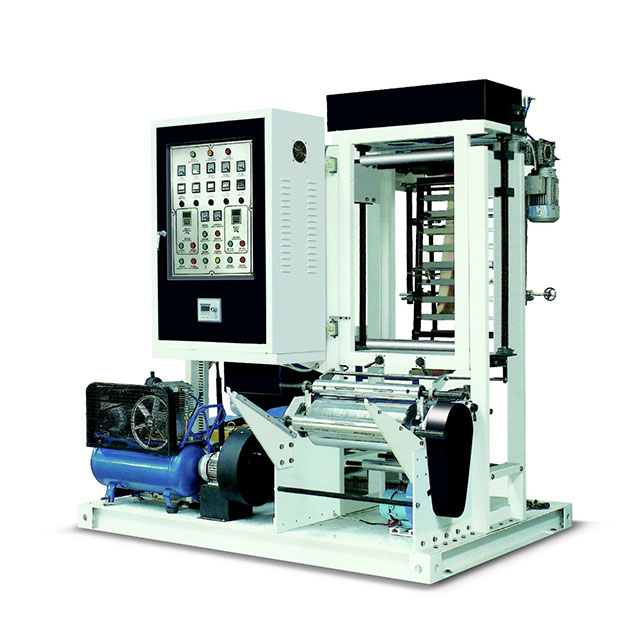

TS-ABA1000/1200/1500ABA Co-Extrusion Blow Molding Machine

Co-extrusion A+B+A combination film blowing machine, whether producing HDPE material or LDPEAnd LLDPE materials, have unique characteristics. Improved thinning through multi-layer co-extrusionThe physical strength of the film can be reduced by one host by using one host for the inner and outer layers.configuration, and at the same time achieve the purpose of reducing costs, energy saving and low consumption. This unit extrudesThe machine, barrel and screw are all made of high-quality alloy steel, with tight nitriding and precision machining.With optimum hardness and corrosion resistance, specially designed screw for high output, plasticizinggood. Suitable for blowing low density polyethylene (HDPE) linear low density polyethylene(LLDPE) and other plastic films, widely used in food, clothing, garbage bags, back Heart bags and other civil and industrial packaging.

| Model | TS-ABA1000 | TS-ABA1200 | TS-ABA1500 |

| Screw diameter | ¢55x2 -¢60x1 | ¢60x2 -¢65x1 | ¢65x2 -¢70x1 |

| Screw length | 28 : 1 | 28 : 1 | 28 : 1 |

| Screw speed | 15-150r/min | 15-150r/min | 15-150r/min |

| Main motor power | 15kwX2 18.5KwX1 | 18.5kwX2 22KwX1 | 22kwX2 30KwX1 |

| Single extruder output | 50Kg/h | 80Kg/h | 100Kg/h |

| Die Specifications | ¢150 ¢200 | ¢200 ¢250 | ¢250 ¢300 |

| Film thickness sided | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm |

| Film Max.Folding | 1000mm | 1200mm | 1500mm |

| The total electrical capacity | 76Kw | 88Kw | 102Kw |

| Dimensions | 6600x4100x5000mm | 6800x4300x6000mm | 7000x4800x7500mm |

| Weight | 6T | 6T | 10T |