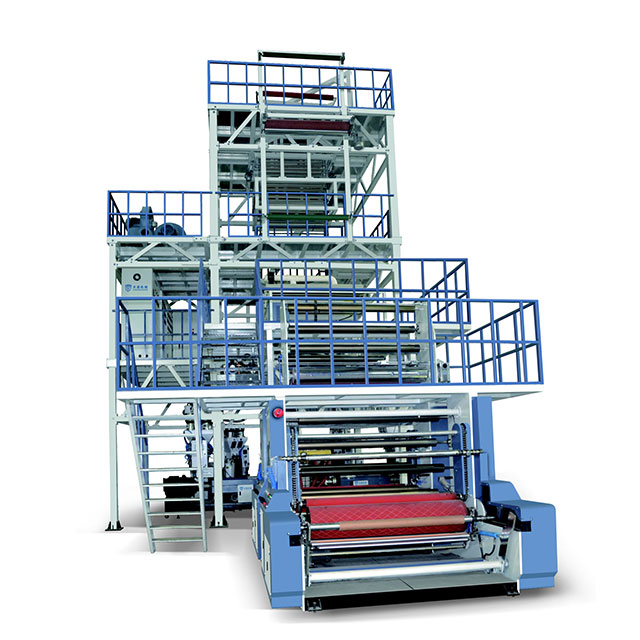

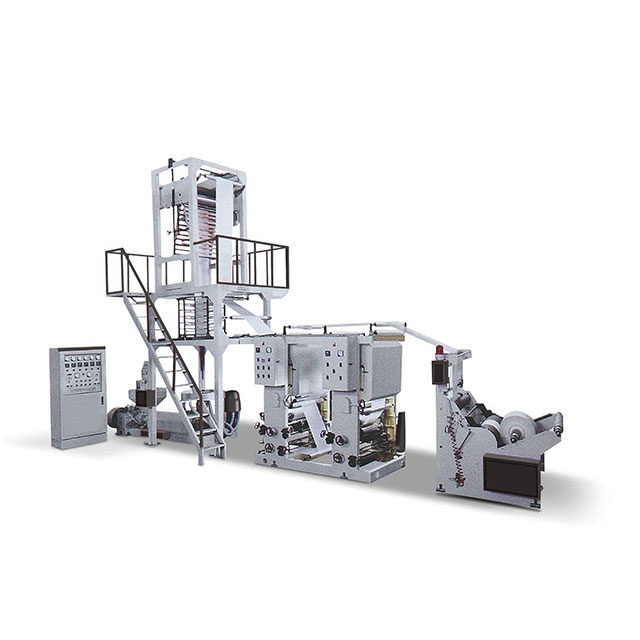

You are here:Home » Products » Film Blowing Machine » TS-2J-50/55/65Two-layer Co-extrusion Rotary Die Film Blowing Unit

TS-2J-50/55/65Two-layer Co-extrusion Rotary Die Film Blowing Unit

TS-2J-50/55/65

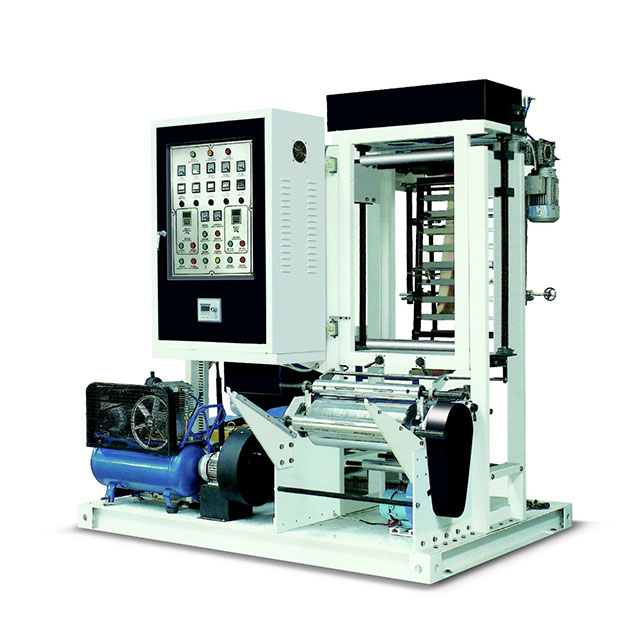

1. automatic suction machine

2. Surface Treatment

3. Air Cooling device

4. The air compressor

2. Surface Treatment

3. Air Cooling device

4. The air compressor

The unit extruder barrel and screw are made of high quality alloy steel after nitrogen treatment and precision machining, with the best hardness and corrosion resistance. Auxiliary set the platform railing table, so easy to operate and configure a foam ring. Coiling device double, double cut, which adopts torque motor to keep proper tension, winding and tidy. Changing easy. Suitable for blowing low density polyethylene (LDPE) high density polyethylene (HDPE), linear low density polyethylene (LLDPE) plastic film, widely used in food, clothing, garbage bags, vest bags and other consumer and industrial packaging.

| Model | TS-2J50 | TS-2J55 | TS-2J60 |

| Screw diameter | ¢50x2 | ¢55x2 | ¢60x2 |

| Aspect ratio | 28 : 1/30 : 1 | 28 : 1/30 : 1 | 28 : 1/30 : 1 |

| Diameter of film | 600-1000mm | 800-1500mm | 1000-1800mm |

| Single film thickness | 0.03-0.20 | 0.03-0.20 | 0.03-0.20 |

| The maximum yield | 80kg/hr | 120kg/hr | 150kg/hr |

| Host power | 15kw X 2 | 18.5kw X 2 | 22kw X 2 |

| Average power-consume | 55kw | 68kw | 90kw |

| Dimensions | 6500x5500x5500mm | 7500x5800x7500mm | 7800x6400x8000mm |

| power supply | 3.8V,50Hz,3Phase | 3.8V,50Hz,3Phase | 3.8V,50Hz,3Phase |