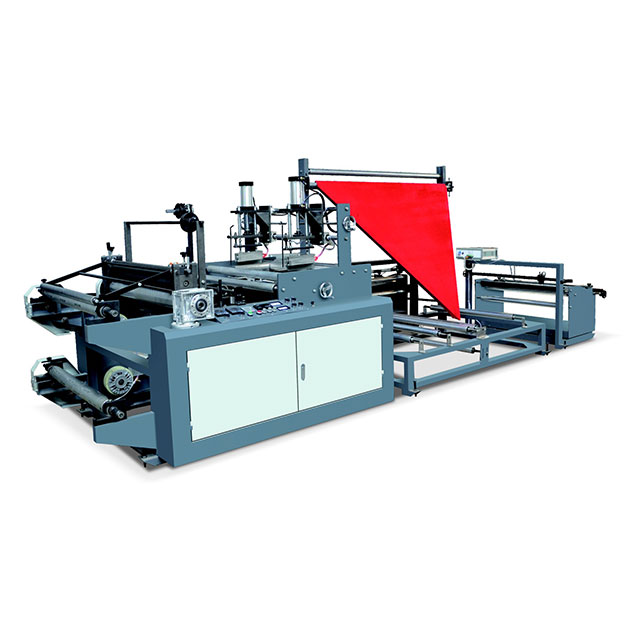

TS-LΦ 55/75x1250New type high speed fully automatic 2 layer / 3 layer co-extrusion stretch film machine

long Iife,energy saving features and it is modified and designed based on the years’experience on the

cast equipment manufacturing and the production experience from the customers, combined with the

advanced technology from oversea, The machine group is mainly for the production of LLDPE film, LDPE

film,PE film, CPE film and PEVA film etc;it adopts advanced intelligent industrial controlling system,with

automatic hidden, cutting saw, automatic cutting and rolI change, automatic paper core unloading and

Ioading system which ensures the easy and safe operation, a tighter and more even roll winding. All the

designs ensure the film quality, enhance the production efficiency, lower down production cost and create

more value. The installation of swing system on the subsidiary machine can enhance the evenness and

appearance of the film rolls which make the products more competitive.

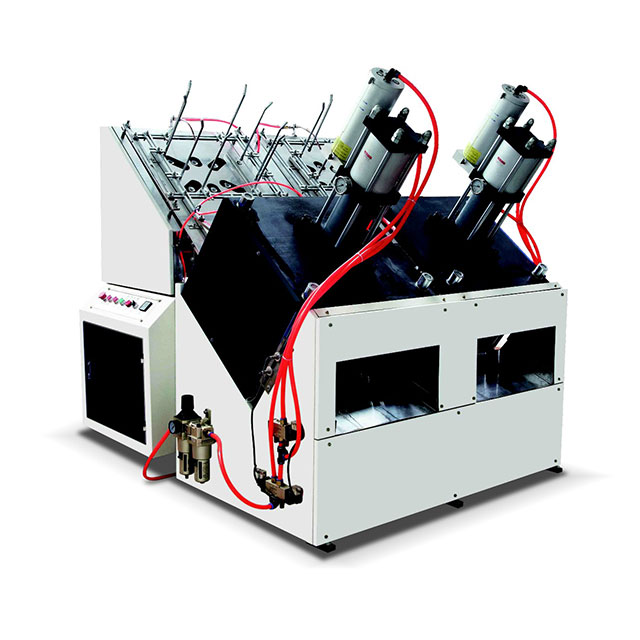

The alloy screw adopts special mixing function and high plasticizing performance design which combines the

imported static mixer to ensure the good plasticization, uniform color and great increase in the extruding capacity.

The T-die is made of imported high quality mould steel which is processed by high accuracy treatment it prevents

fhe T-die from deformation in long time usage and the casting is smoother and more stable.

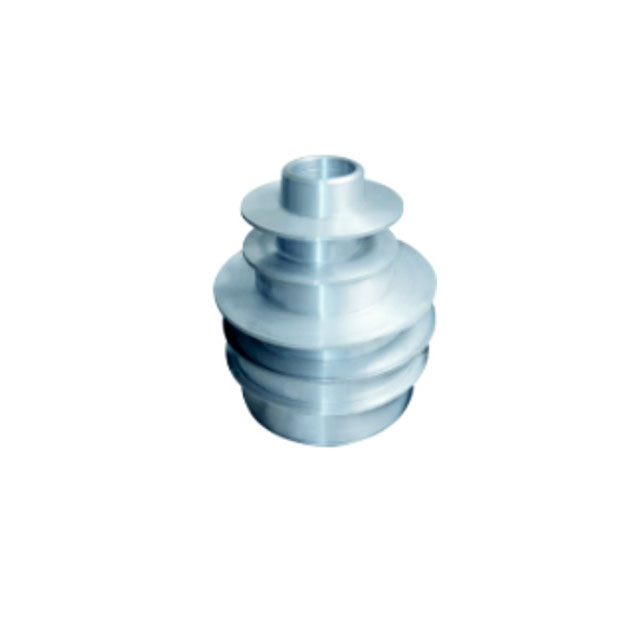

The design inside the cooling roller Is bi-directional and in circuit. The roller is with built-in spiral runner which

ensures the even surface temperature.

The winding station can move back and forth.It adopts advanced torque motor which can adjust the speed and the

width of the film freely.

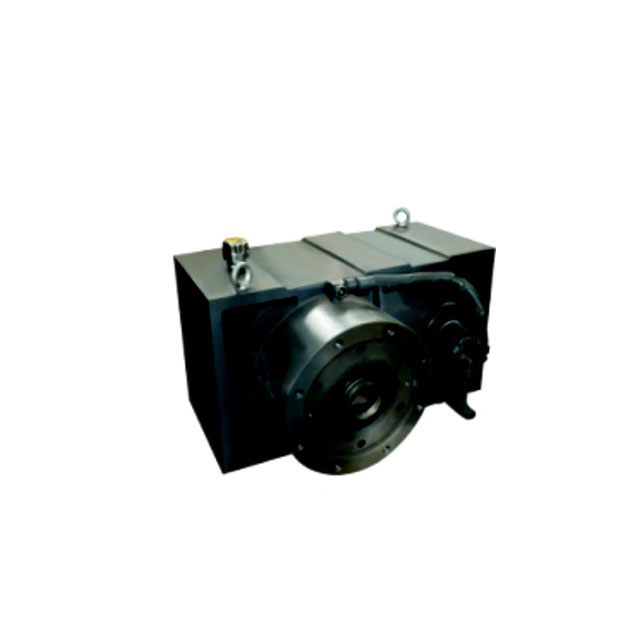

Melting gear pump and PID controlling system

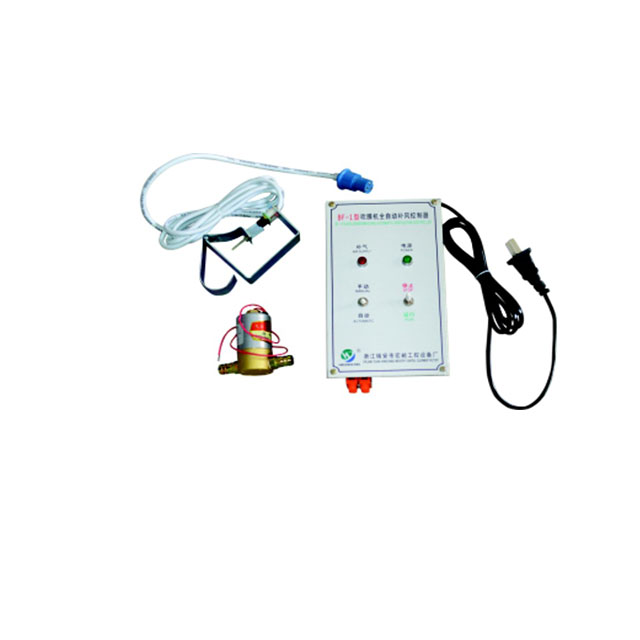

Micro-computer temperature controller with touch

screen for accurate temperature control

Automatic air shaft loading

Automatic screen changer with hydraulic station